My father loves his dog. In some respects, this is a perfectly normal state of affairs, but when one probes more deeply it becomes a bit odd. First off, my father has, for as long as I can recall, claimed to despise dogs. We had them growing up. He hated them. Wanted nothing to do with them. Actually took a swing at one once and, thinking better of it mid-throw, pulled his punch and ended up hitting a post accidentally instead, breaking his hand. Speaking of hands, when out and about, whenever he saw someone walking a dog around the neighborhood he would form his right hand into an imaginary pistol and “shoot” the dog being walked. On more than one occasion, the animal’s poor owner noticed this bit of theatrics and recoiled in horror. My father has always hated dogs.

Now, it’s clearly rational to think that the slow march of time might soften the heart and that there might be a place for a dog in his world. A nice black lab, perhaps? Or a blue tick hound? Maybe a shepherd of some kind? A terrier? Any of these have a degree of masculinity and utility about them that would make them seem to fit with his persona. The dog he dotes over, however, is this thing:

It’s a fluffy little furball with an underbite, an annoying propensity to howl, and a rather disinterested relationship with humanity that smacks of superiority. Honestly it’s more like a cat. And my dad is definitely not a cat person.

Anyway, this is a long-winded introduction that’s necessary to help us understand that in much the same way construction workers will etch their names in foundations in places that won’t be seen when the building is finished, but that marks forever their contribution to the effort, my father feels compelled to scribble his dog’s name, Paca (Palo Alto, California) on the boat to forever enshrine it, entombed in epoxy and paint, but there for the knowledgeable.

And so, from time to time, I find “PACA” scrawled on the boat without explanation or excuse. I’ve had enough. Today I started fighting back. Here you can see my addendum to his scribblings. I’m going to make a habit of this going forward.

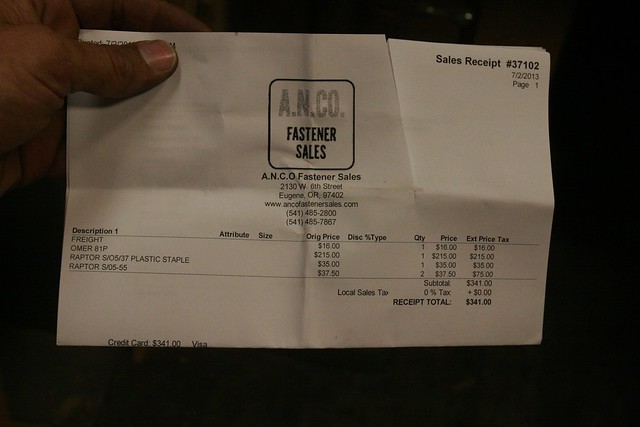

As for the boat, we’re making progress on the bottom planking. Here’s a shot as of this morning, with one side completed and the other side partially complete and with a second layer started. Since this photo we’ve finished the first layer on the port side and done the aft part of the starboard. We’ve got about half the boat still to go on this last layer of bottom planking and then we’ll be done with the planking! I’m looking forward to that. I’m getting a little tired of spiling and stapling at this point. It’ll be nice to do something – anything – else.

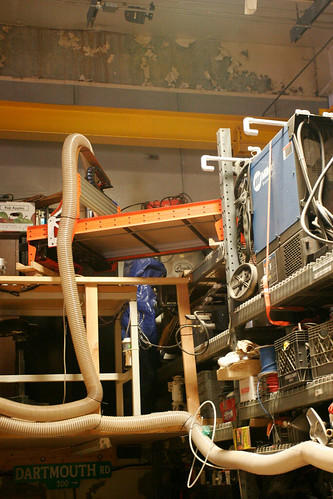

Oh, and I got the CNC machine up and running. Still a bit more to do for it to be operational, but here’s a shot of it cutting out its own vacuum table plenum. Really all I need to do at this point is finish the plenum and then plumb up the vacuum system and it’ll be DONE.

It’s kinda funny having this tool up on the mezzanine, bridging between the table and the pallet rack, but it’s really turning out to be a pretty good place for it. All the work happens “inside” the machine, and it’s not hard to get a piece of material that’s as big as the machine will allow up there, so it gets it out of the way.

That’s it for today. Onward and upward!

-Ben